Skills and Know how:

Development

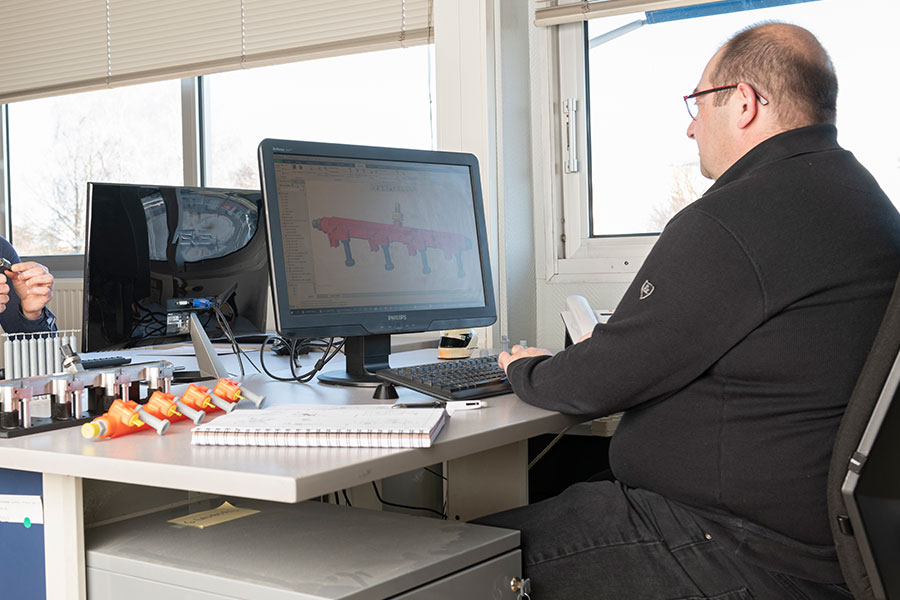

Design & Development

+ CAO systems with PTEC CREO & CATIA

+ Analysis systems: ANSYS-WORKBENCH, LS DYNA SC TETRA CFO simulation

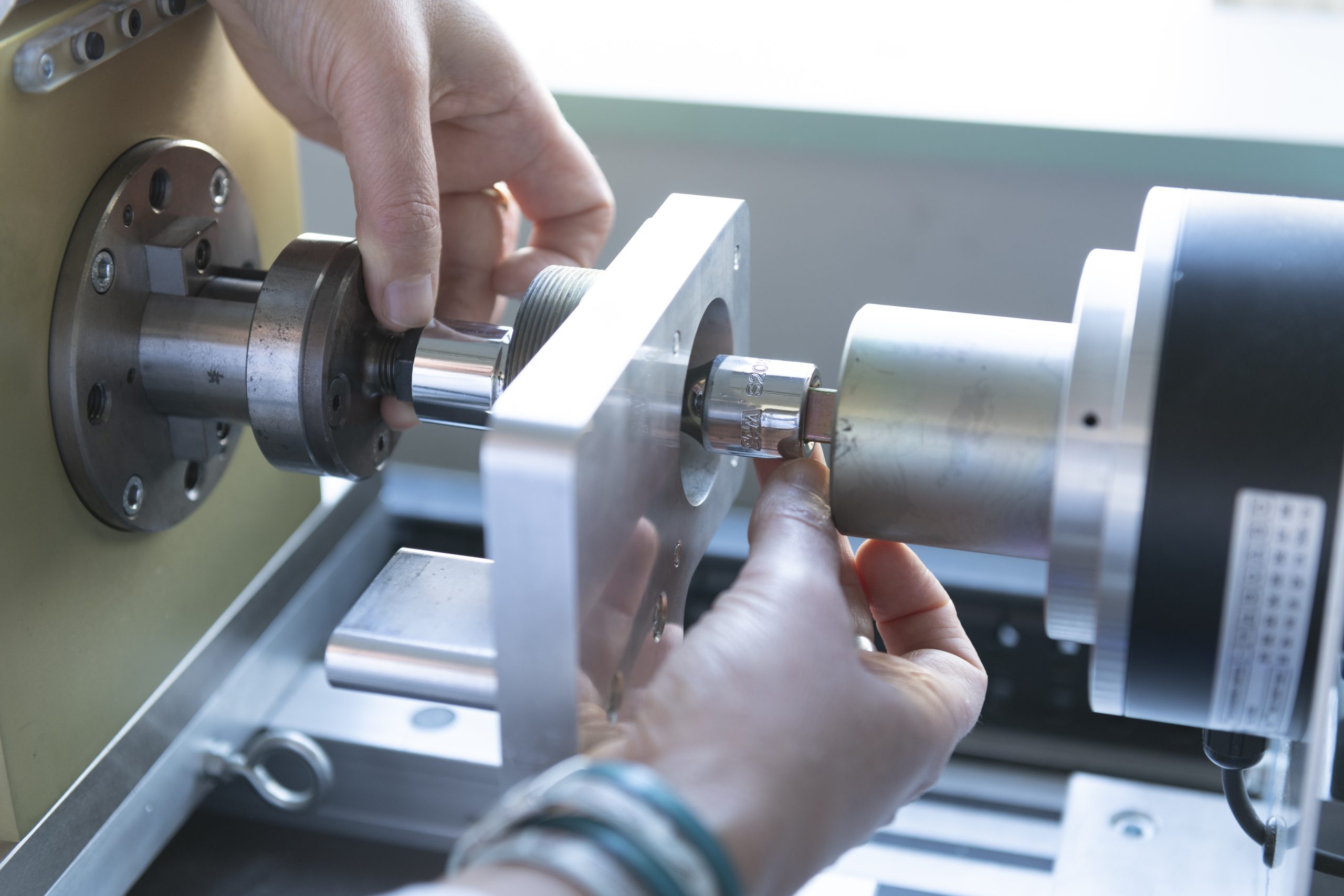

Prototype Development and Production

+ Tube lines

+ Auto lathe lines

+ Fully capable prototype shop

+ Machining center CNC

+ 3D printing

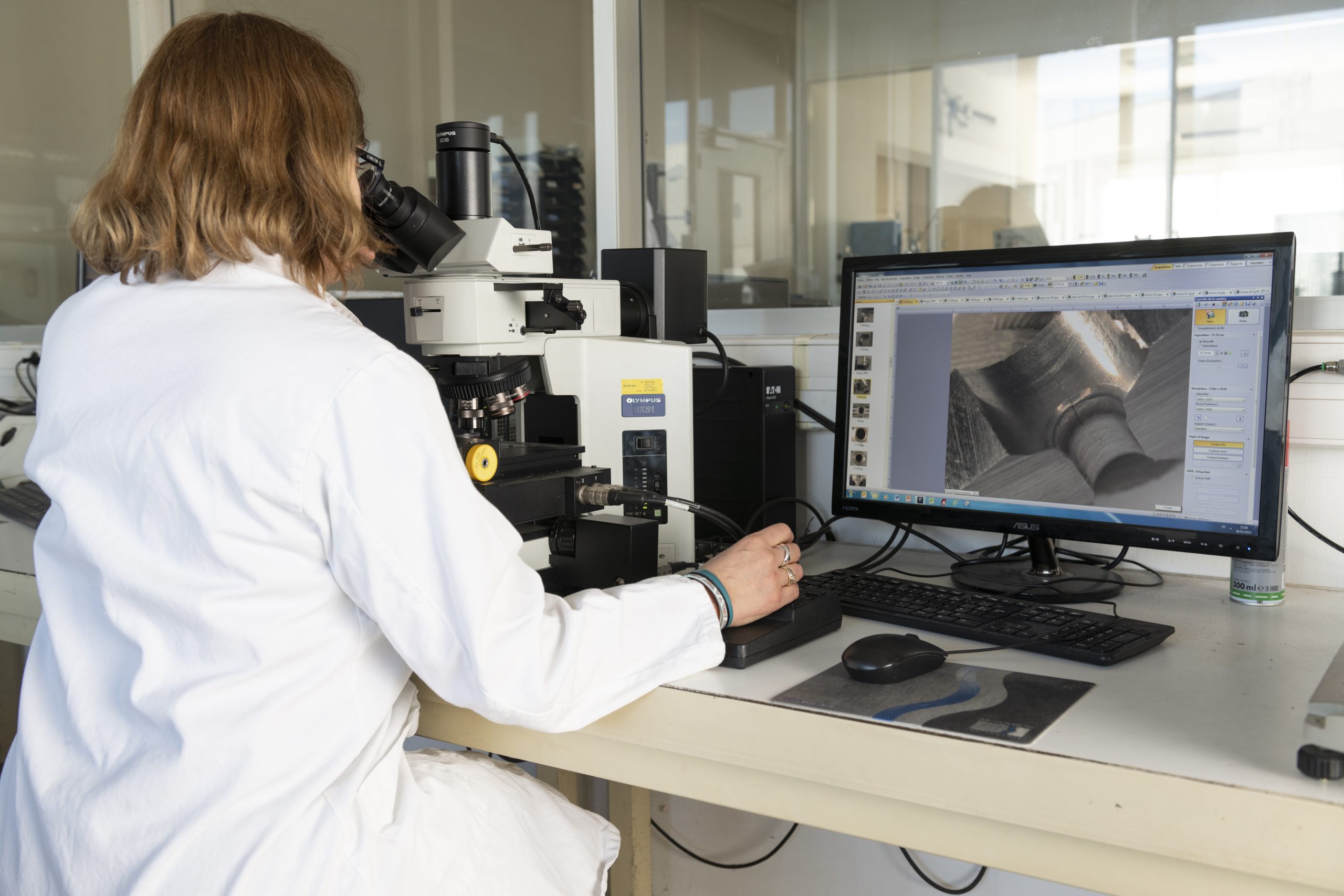

Test & Analysis

+ Tightening, stress & strain hardening

+ Metallographic analysis

+ Endoscopic analysis

+ Mechanical & chemical testing

+ Tightness testing

+ Climate chambers

+ Salt spray tests

+ Cleanliness testing bench

+ Shock and vibration simulation for durability testing

Manufacturing processes

Machining

Milling Duncha manufacturing strength:

3, 4 and 5 axis CNC Gun Drill machine

4 Axis Milling:

- 550 x 400 x 425 mm

- Max Spindle Speed: 12 000

Models: CHIRON FZ15 W (1)

5 Axis Milling:

- 800 x 800 x 550mm

- Max spindle Speed 10 000

- Models: Hermle C42 (2)

- 550x 400x 400 mm

- Max spindle Speed 15 000

Models: CHIRON FZ 12 (1)

1 Gun Drilling:

- Pressure 100 bars

- Ø maxi 18mm (Material 1000 Mpa)

- Lg maxi 700 mm

Models: IXION TLW 3-700.2 (1)

Turning Duncha manufacturing strength:

Single Spindle

• Chuck Size: 250mm

• Models: MAZAK QT 200 (1)

Twin Spindle

• Models:

- STAR SR32 (1)

- STAR SB 20 (8)

- BIGLIA B545 YS (1)

Automatized line:

Turning, control, Cleaning & Packaging

Part dimensions:

Slug/piece = ∅ 210mm – Lg 500mm

From bar = ∅ 20mm – Lg 200mm (some possibility in ∅ 32mm – Lg 300mm)

Tube process within Duncha manufacturing strength:

Forming by cold pressing

- 3 automatic machines burger (70000 t/days)

- 3 manual forming machines (Crippa and silfax)

Tube Bending

- 5 cnc including 2 managed by robot (staubli)

- About 10 automatic bending stations

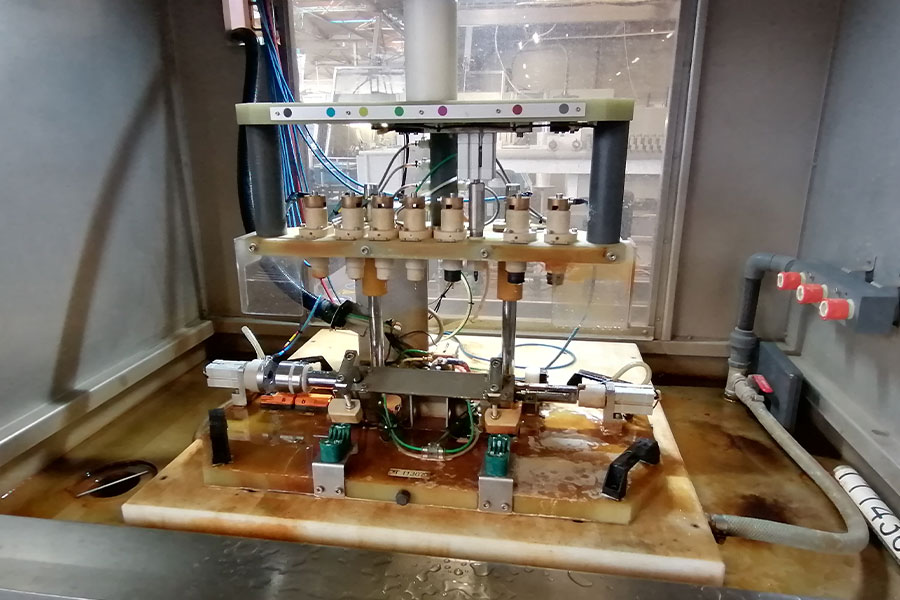

Autofretting

- 5 aquarese machines

- 12 automatic autofretting stations

Washing and Cleanroom

- Particle size: less than 150 micron

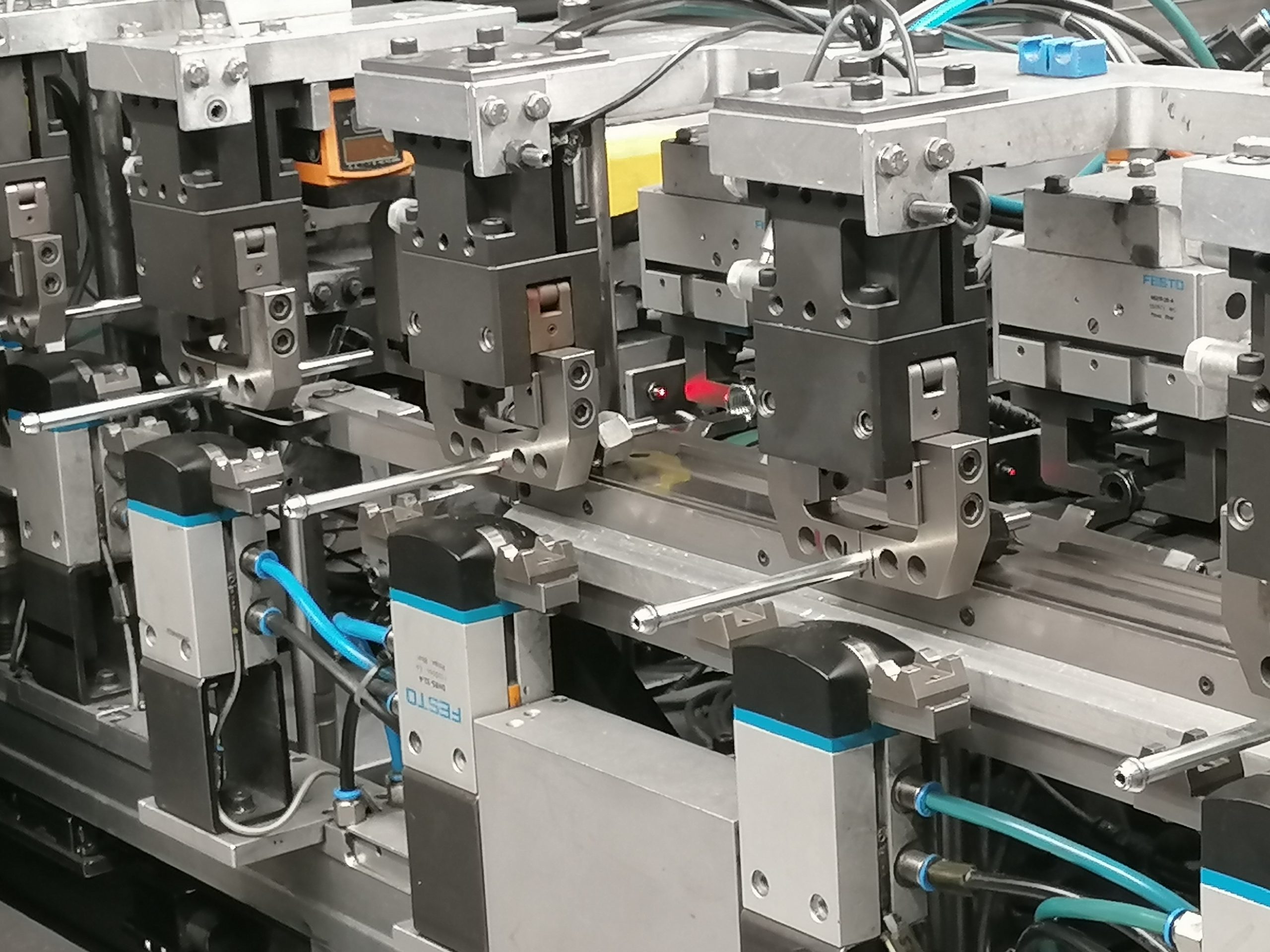

Assembly line:

Other processes within Duncha manufacturing strength:

ECM:

- Single Spindle

- WORKING AREA Size: 1000x800x800 mm

- Models: SERMATEC (1)

AUTOFRETTAGE:

- Pressure From 5000 bars to 9000 bars

- Precision: +/- 100 bars

- Models: Internal development (x2)

CLEANING:

- Carrousel cleaning Machine

- Clean Room (75m2) (2)

- Cleanliness inspection VDA19 & ISO/DIS 16232

- Models: CHIRON FZ15 (1)

ASSEMBLY / TESTING:

- Pressure Sensor testing

- PCV pressure testing

- High pressure leakage testing

- Models : Internal development (X2)

CONTROL/ MEASUREMENT

3D MEASUREMENT EQUIPMENT

Certifications:

IATF 16949 – AS9100 (Rev D) – ISO14001